Compare Cyngn

vs. Vecna Robotics

Industrial autonomous vehicle solutions are important for streamlining your operations. But how do you decide which provider is best for your business?

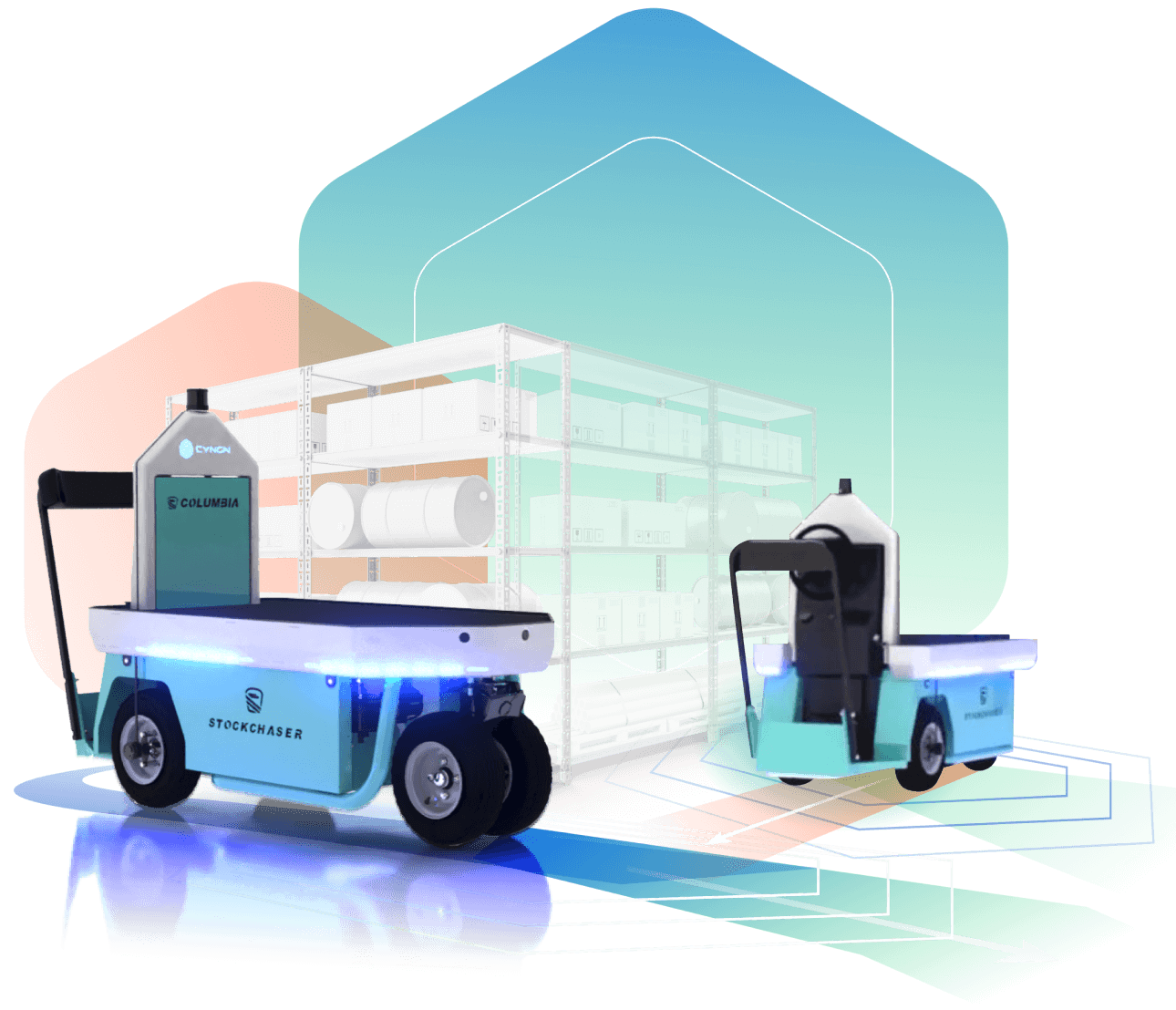

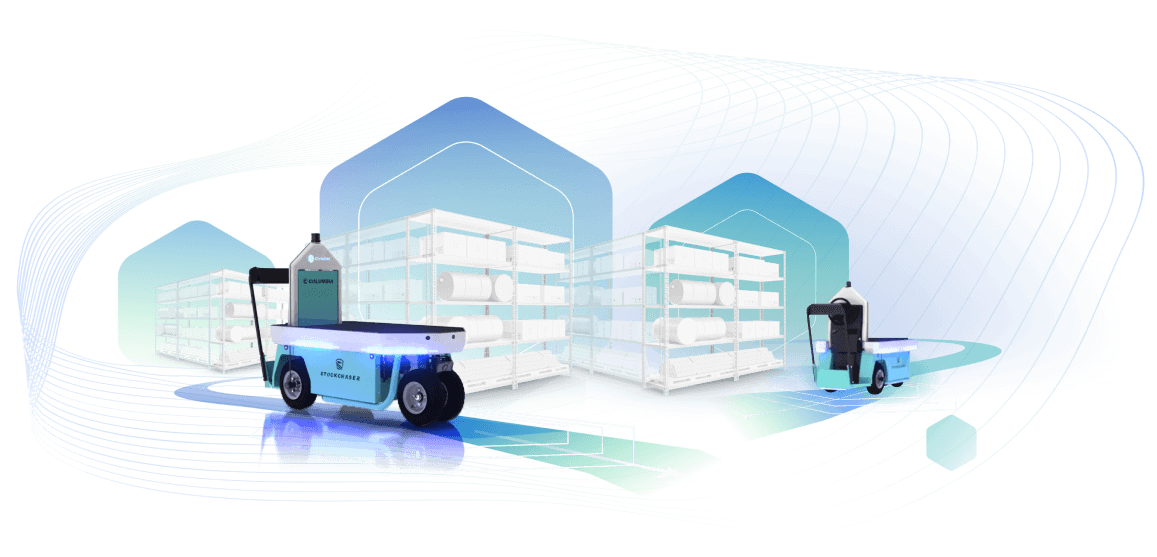

This guide outlines the differences between industrial autonomous vehicles offered by Cyngn and Vecna Robotics. Below, you will learn how Cyngn’s DriveMod Stockchaser and Vecna Robotic’s ATG differ.